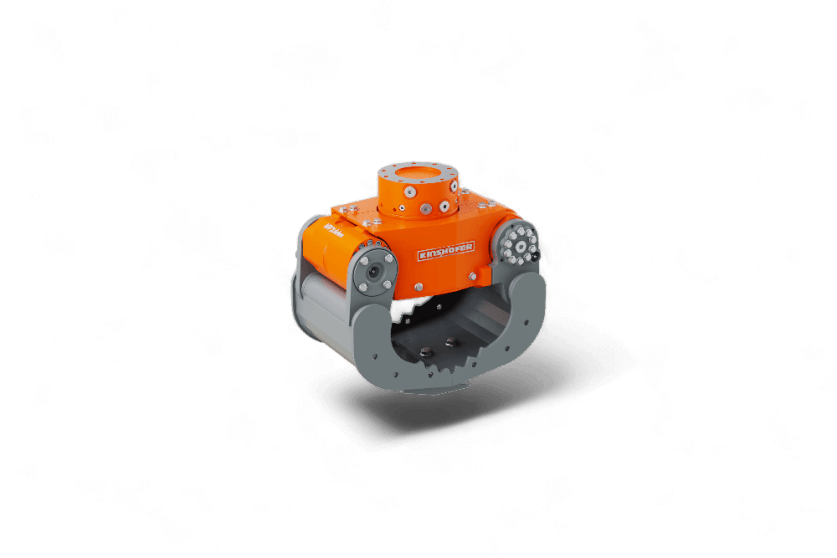

KINSHOFER multi-purpose gripper A02HPX

Find the nearest sales representative

Buy second-hand

Sold

Kinshofer grabber A02H

Year of build

2023

Weight

135

kg

Condition

Price

without VAT

4'990

CHF

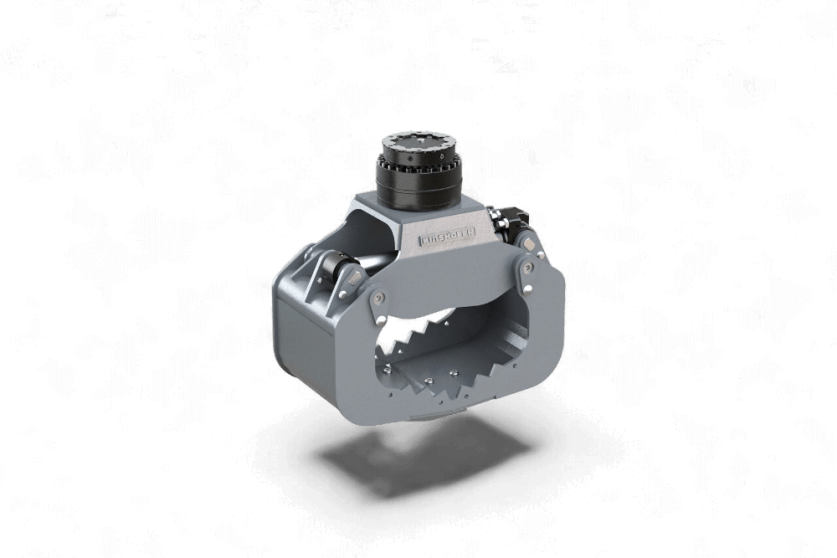

KINSHOFER multi-purpose gripper A04H

Year of build

2023

Weight

190

kg

Condition

Price

without VAT

6'800

CHF

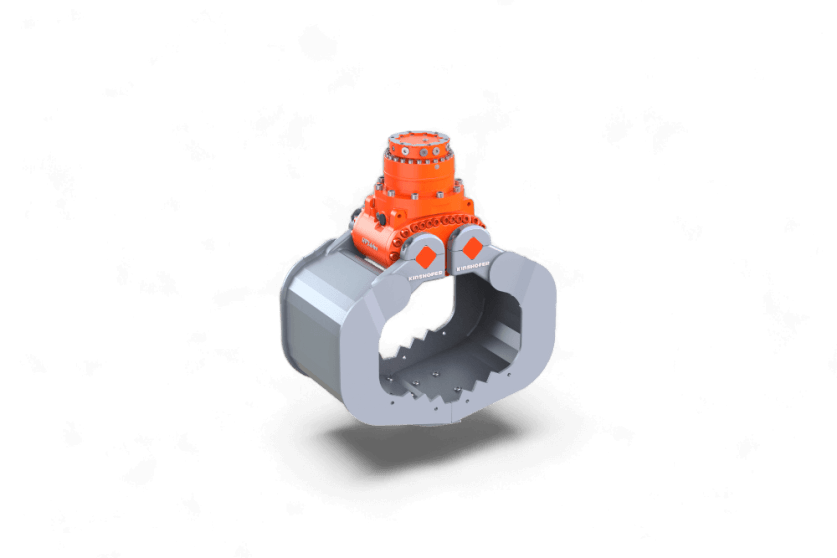

KINSHOFER grabber A04H

Year of build

2024

Weight

190

kg

Condition

Price

without VAT

6'500

CHF

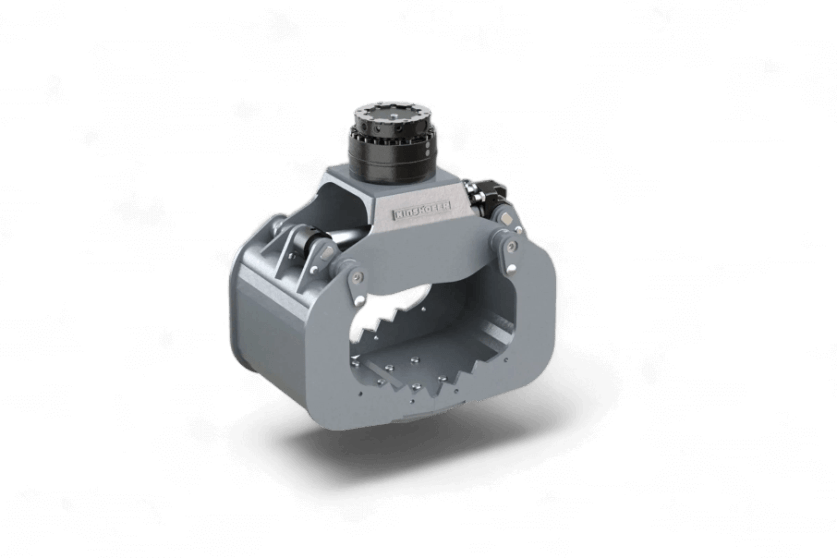

KINSHOFER grabber A06HPX

Year of build

2024

Weight

340

kg

Condition

Price

without VAT

6'990

CHF