The high density and strength of ultra-high performance concrete UHFB / UHPC or ultra-high performance fiber-reinforced concrete presents the industry with new challenges. As ultra-high performance concrete hardens very quickly, a compact forced mixer close to the consumer is essential.

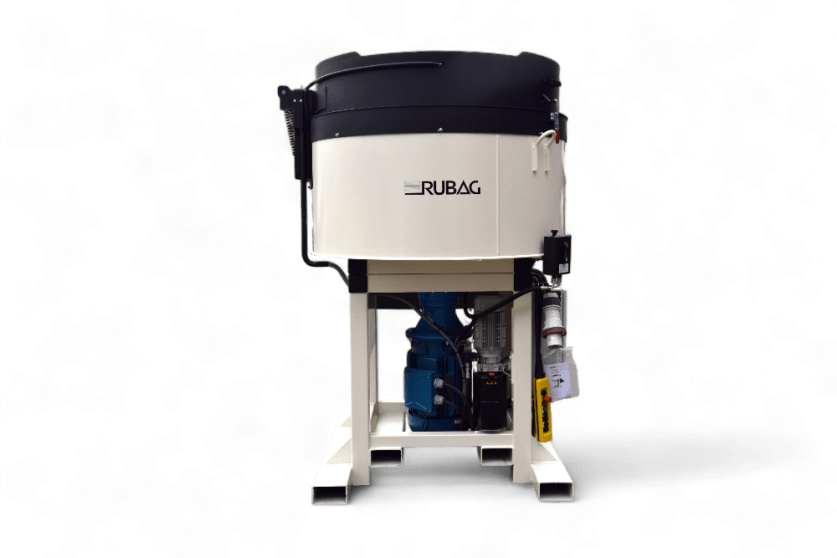

In order to meet the special requirements of this demanding concrete mix, our proven forced mixers have been further optimized. A special, low-resistance arrangement of the mixer parts and the low-maintenance high-performance gearbox ensure highly homogeneous mixing results. Our RUBAG UHFB forced mixers are explicitly recommended by leading construction companies and concrete manufacturers.

Advantages of this forced mixer

- Special mixing unit for UHFB/UHPC: Optimized for ultra-high-strength concrete.

- Powerful motor: Extra powerful for maximum efficiency.

- Maintenance-free: No need for regular maintenance.

- Durable & robust: Drum shell made of highly wear-resistant sheet steel.

- Low-noise operation: Minimizes noise pollution during use.

- Compact: A space-saving alternative to large mixing plants and concrete trucks.

Standard equipment

- Stationary with forklift bags

- Direct drive by Oelbad electric geared motor with

Motor protection reversing switch

- Switch box

- Hinged protective grille with limit switch

- Digital flow water meter

- Hydraulic slide opening at the bottom + discharge funnel

- CEE 125A plug

Optional additional equipment

- Weighing system under mixer

- Paint finish as desired (RAL color)