With their patented bi-turbo technology, the CompAir TurboScrew compressors C200TS to C270TS set new standards in terms of diesel efficiency, weight and environmentally friendly compression performance. With a feather-light weight of just 3,500 kg, these construction compressors offer the customer a real advantage. And yet, when purchasing the machine, the customer can rely on outstanding performance with minimal environmental impact.

Two unique technologies

Bi-Turbo

The patented Bi-Turbo technology of CompAir compressors is characterized by an innovative pre-compression of the compressed air by means of an additional turbocharger. Thanks to this unique technology, these compressors achieve an impressive energy output that is up to 14 % higher than conventional technologies. Fuel consumption is also significantly lower. Under normal operating conditions, varying between idle, part load and full load, CompAir TurboScrew construction compressors consume up to 30 % less diesel compared to most conventional air compressors on the market.

The result is lower operating costs.

SCRT® (Selective Catalytic Reduction Technology)

The new TurboScrew compressors have been equipped with a recognized SCRT® system (Selective Catalytic Reduction Technology). This exhaust gas aftertreatment system removes almost all soot particles and nitrogen oxides from the diesel exhaust gases, resulting in extremely clean performance.

Further advantages

-

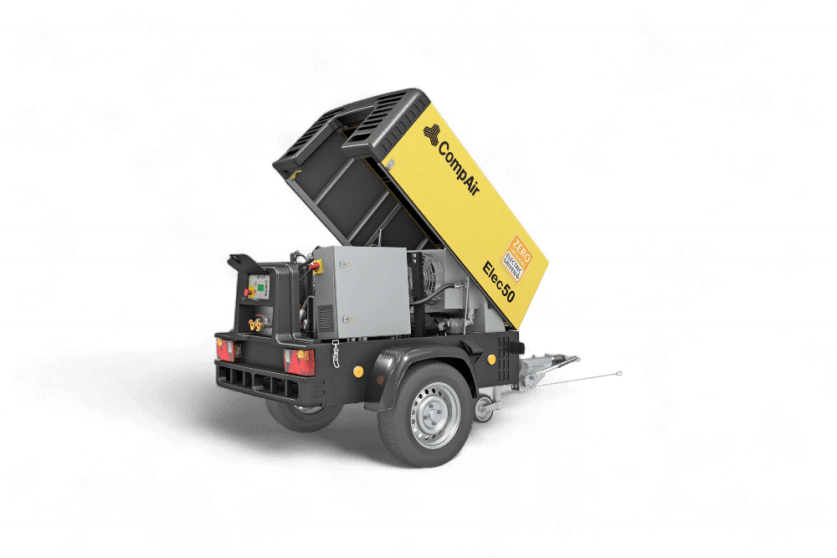

Can be driven as a trailer: With a total weight of only 3.5 tons, the compressors can easily be transported in a transporter or SUV. Only an inertia brake is required.

-

Environmentally friendly and efficient: These compressors offer up to 30% lower fuel consumption compared to conventional compressors. The environmental impact is minimal, and equipped with an exhaust gas aftertreatment system (SCRT®), they meet all legal Stage V limits.

-

Powerful and reliable: Electronically controlled CUMMINS QSB 6.7 engine ensures a high output of 180 to 224 kW.

-

Engine protection: An electronic monitoring system for the engine and compressor ensures automatic shutdown in the event of faults such as low engine oil pressure, excessive cooling water temperature or excessive charge air temperature.

-

Easy to operate: The operating pressure can be set quickly and easily in 0.1 bar increments, allowing precise adjustment to the requirements of the respective application.

-

Maintenance-friendly: Large, wide-opening front and side wing doors enable quick and easy maintenance. In addition, the diesel particulate filter (DPF) can be cleaned with a conventional high-pressure cleaner.

Optional accessories

- Alternative design: body frame or skid frame

- Height-adjustable drawbar

- Aftercooler with heat exchanger and bypass